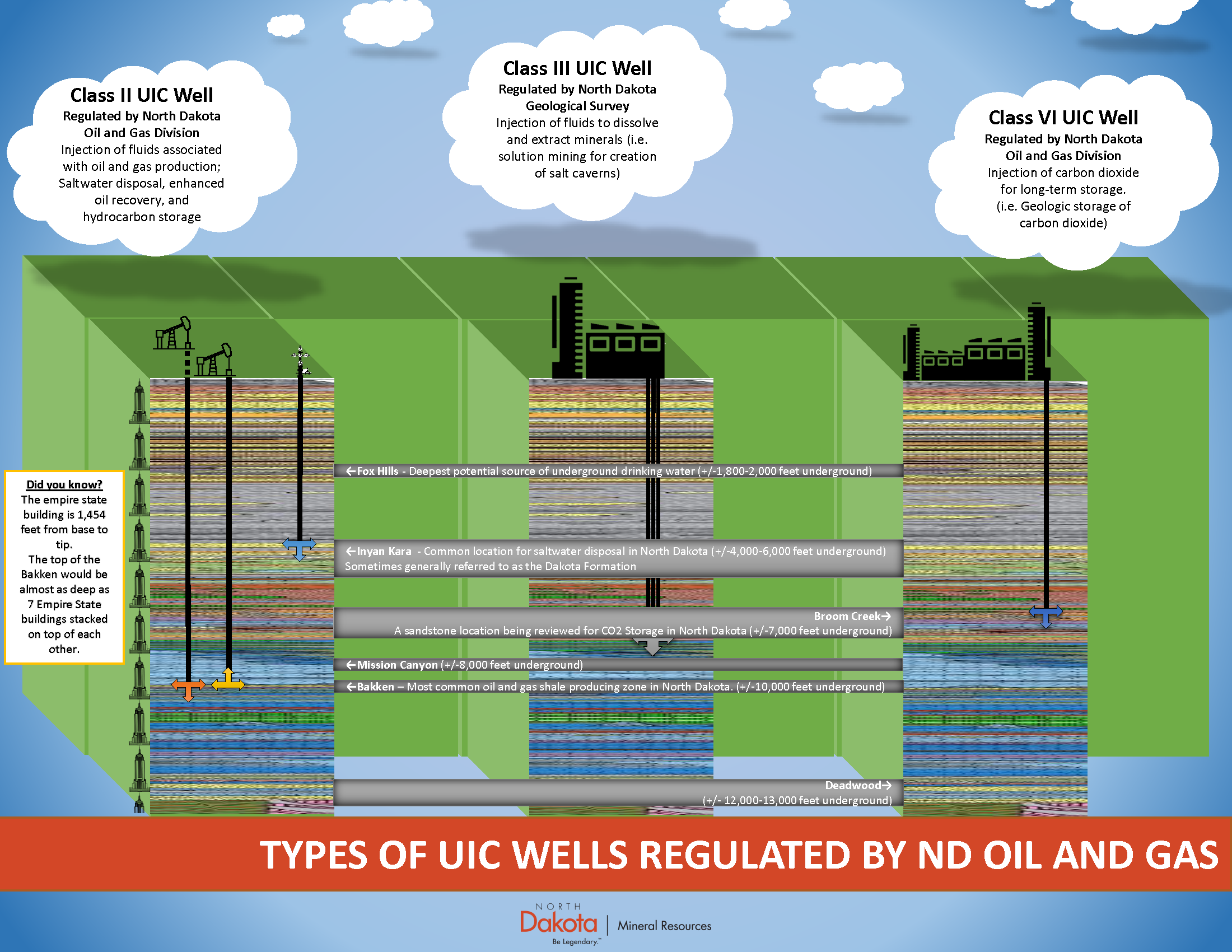

What is Underground Injection Control?

The Underground Injection Control program (UIC) is a nationwide program pursuant

to the Safe Drinking Water Act (SDWA) and is overseen by the Environmental Protection Agency (EPA). The UIC program was established to protect underground sources of

drinking water (USDW) by regulating the permitting, construction, operation and closure of injection wells that place fluids underground. There are six classes of UIC

wells and the Department of Mineral Resources has primacy over Class II and Class III wells.

Click here to see a larger view of the above slide

How does the UIC program protect USDW's?

The cornerstone of the UIC Program is three layers of protection for USDW's.

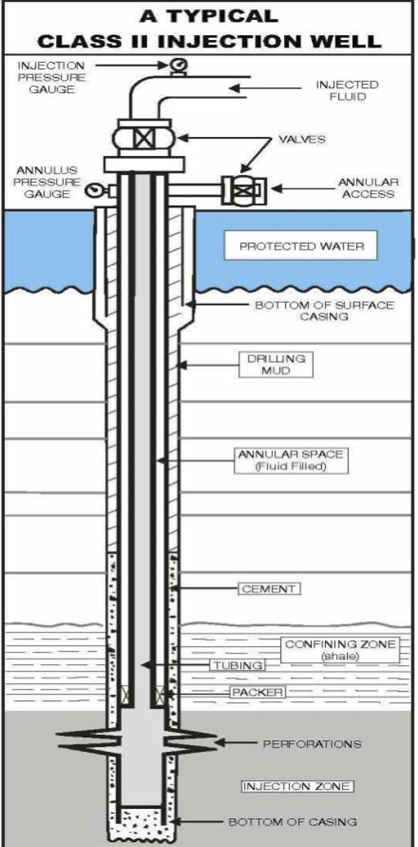

An injection well's construction with three layers of protection helps to ensure that groundwater is protected. The first layer of protection is surface casing-a steel

pipe that is encased in cement that reaches from the ground surface to below the deepest USDW. The second layer of protection is the production casing-a pipe placed in

the wellbore from the ground surface to the well's total depth and permanently cemented in place above the injection formation. The third layer of protection is the

injection tubing string and packer that conducts the injected fluid down to the perforations at the bottom of the well for injection into an underground formation. With

these well construction standards, all three layers of protection would have to fail at the same time for injection to potentially impact groundwater.

What is Primacy?

Primacy allows states to implement programs through agreements with the EPA unique to their own geology

in order to protect USDW's. North Dakota's UIC regulations meet or exceed federal regulations. EPA approval of a primacy program allows state programs to differ from

federal rules and guidance, as well as from other states, as long as the program is as effective as federal regulations in protecting USDW's.

What are Class II and Class III wells?

Class II injection wells are regulated by the Oil and Gas Division, while Class

III wells are regulated by the Geological Survey. In North Dakota, Class II injection wells are used for enhanced oil recovery and oilfield waste disposal, which is

typically saltwater (brine). Class III wells are used for injecting fluids associated with subsurface mineral mining. While there are no Class III wells currently in

operation in the state, there are a growing number of active Class II wells.

What are Class VI Wells - Geologic Storage of CO2?

What are Enhanced Oil Recovery Wells (EOR)?

Enhanced oil recovery wells are used to help extract additional oil and

natural gas resources that primary recovery was unable to produce. Injection of fluids or gases into the reservoir moves or "pushes" the oil or natural gas to surrounding

producing wells, making the resource available for production. Without enhanced recovery methods these additional oil and gas resources would not be recovered.

What are Saltwater Disposal Wells (SWD)?

Saltwater is a waste product that is produced and separated from oil during the

production process. In North Dakota, just over one barrel of saltwater is produced for every one barrel of oil. Generally, this saltwater is too salty to be recycled so

it must be injected underground well below USDW's. SWD's are the only approved method for disposing of saltwater in North Dakota.

How are EOR and SWD wells permitted and constructed?

Each injection well requires public notice and hearing before a

permit may be issued unless it is within an area permit, (which previously had a public hearing) which allows administrative approval. Area permits are specified by

field and were originally allowed when North Dakota received primacy in 1983. This essentially grandfathered some areas of the state into the program.

Construction of these wells is carefully planned and monitored to protect groundwater sources, with the typical well having three layers of steel casing/tubing as well

as two layers of cement. Once a well begins injection, pressure and wellbore integrity are carefully monitored once a month by our inspectors and a down-hole mechanical

integrity test is required initially and at least every five years or whenever the down-hole portion of the well has undergone maintenance.

Other requirements for the permitting process:

- Surface owners within 1/4 mile must be notified.

- SWD's over shallow aquifers require a geotechnical analysis by a qualified, independent contractor before a proposed location will be considered. This is to determine the suitability of the shallow subsurface geology to protect the shallow aquifer.

- Injection must be into a formation with an upper and lower confining zone to prevent migration of fluids into other formations or fresh water zones. In North Dakota, the disposal zone is typically one half mile to one mile below the surface, into the Dakota Group.

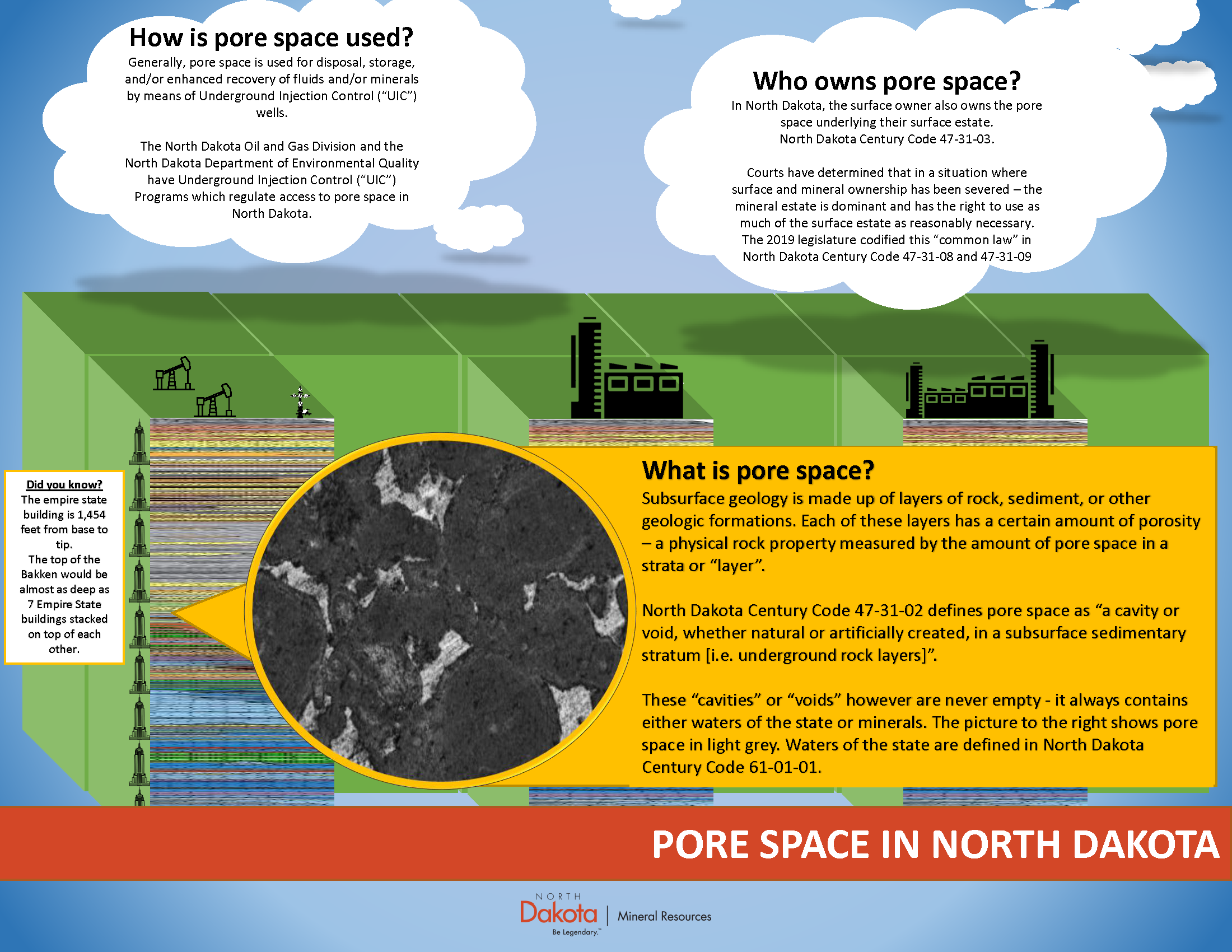

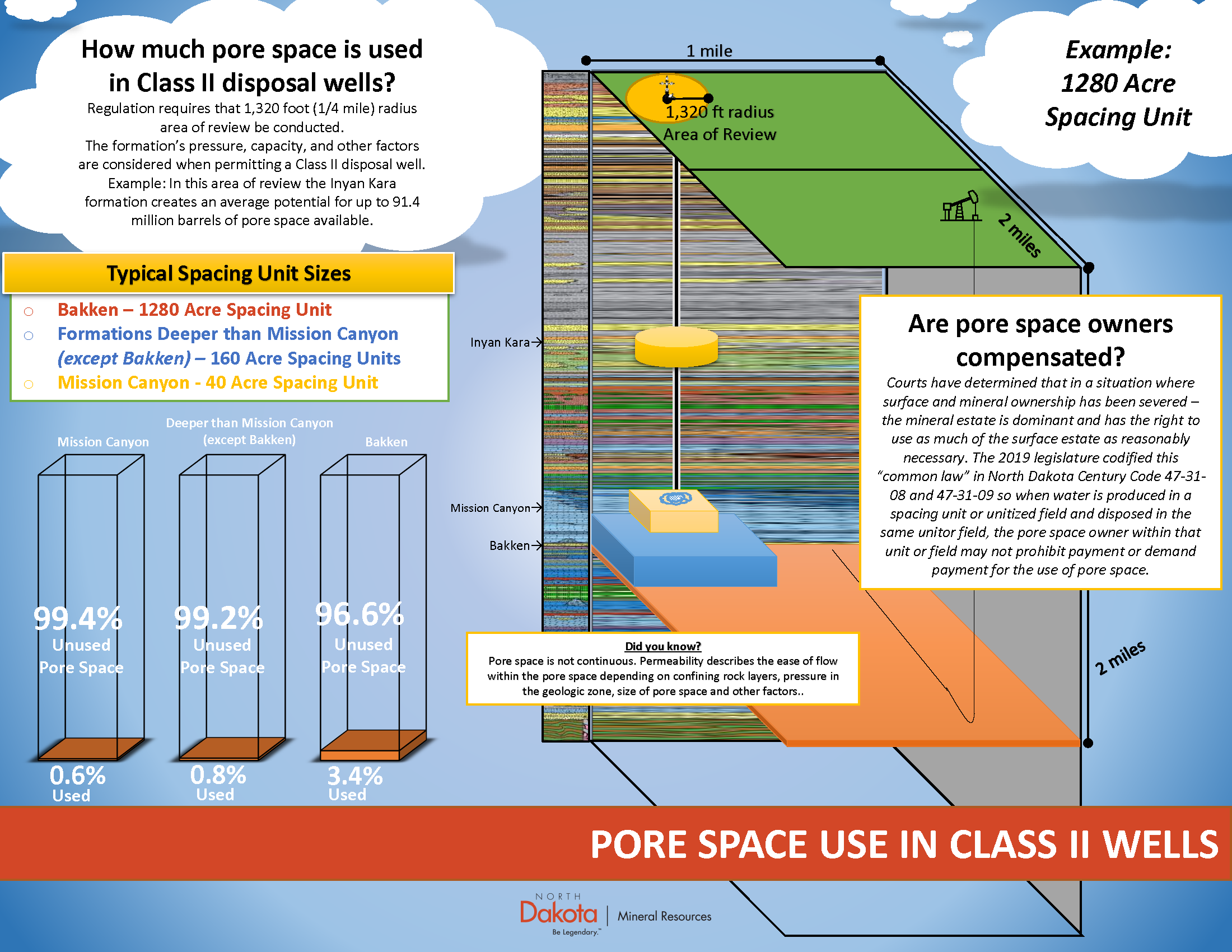

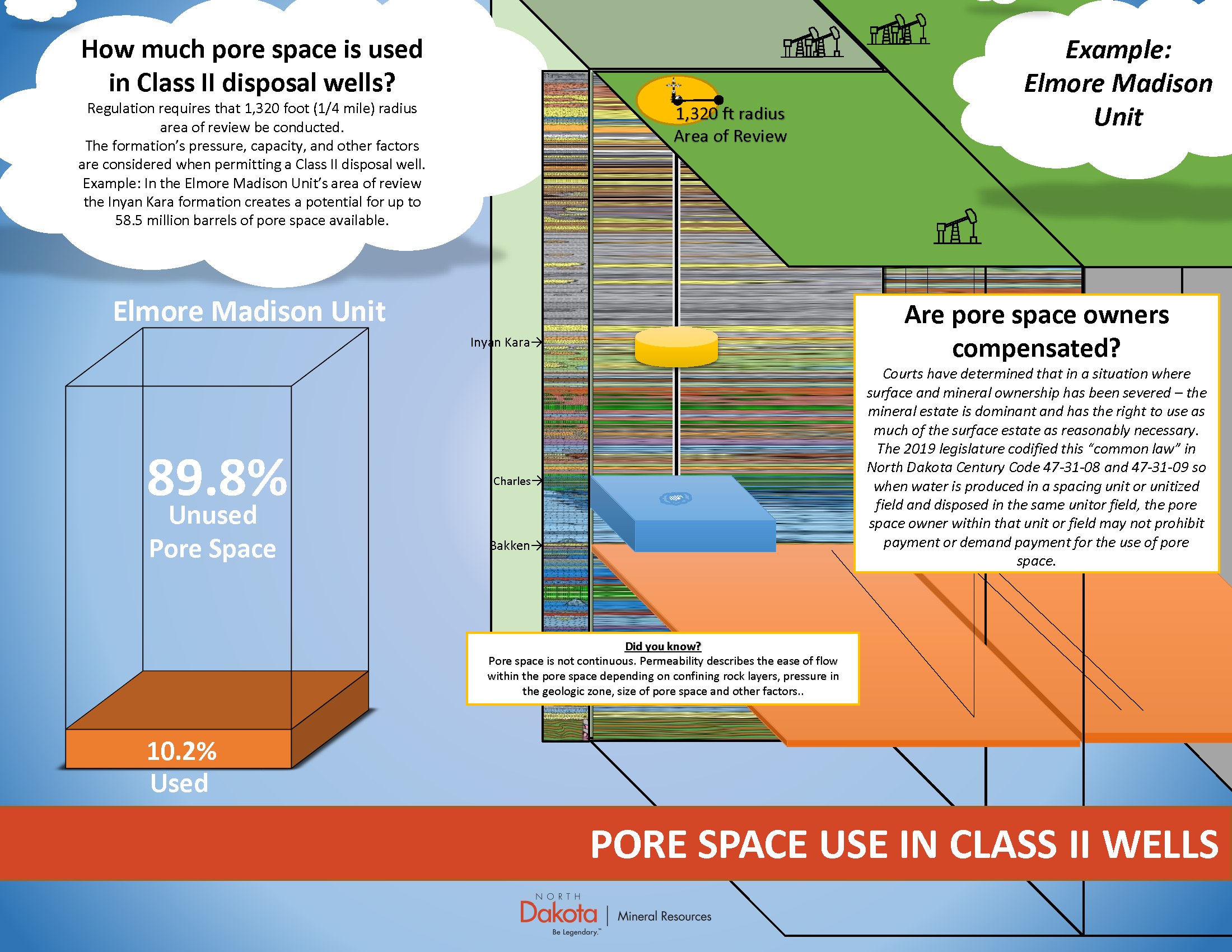

What is pore space and how is it used in UIC wells?

Click here to see a larger view of the above slides

What is a mechanical integrity test?

Mechanical integrity tests are meant to test the ability of the wellbore,

consisting of casing, tubing and packer to contain injection pressure and injected fluids. The tubing and packer are the primary containment system that is monitored

and inspected monthly by Oil and Gas Division field inspectors. The casing and cement are the backup containment system. Mechanical integrity tests are meant to

insure that the primary containment system does not leak and ensures the back-up system will hold if the primary system (tubing and packer) fail between monthly

inspections.

What are reporting requirements for injection wells?

At the beginning of each month, operators of injection wells must

submit to the Oil and Gas Division the beginning and end of month meter readings, the total volume of fluid injected, average injection pressure, a list of the

individual sources of fluid, the type of fluid that was injected and the transportation method (piped or trucked) of the fluid.

Can disposal wells cause earthquakes?

North Dakota geology is very suitable for underground injection of oil and gas

wastes. Disposal injection in North Dakota is typically one-half mile below the deepest underground source of drinking water (USDW) and one mile to two miles above the

granite rock formations where earthquakes originate. However, as a precaution North Dakota has rules in place relative to induced seismicity:

North Dakota requires a map depicting the area around the location where the disposal well is proposed that depicts any known or suspected faults.

Wells must be constructed in a manner that prevents movement of fluids into USDW's or into unauthorized zones.

The North Dakota Industrial Commission (NDIC) may require continuous monitoring up to and including seismic monitors as well as sampling injected fluids and testing of the well.

The NDIC can modify or suspend the well permit at any time. In addition the NDIC may order the operator to cease injection of a well should it become noncompliant.

Current science indicates that earthquakes originate from faults in the granite rock formations that are much deeper and older than the sedimentary rocks where disposal

injection occurs in North Dakota. Other states may have induced seismic activity due to some instances of fluid injection into very deep formations just above the

granite rock formations. The Interstate Oil and Gas Compact

Commission (IOGCC) recently concluded a review of the potential for injection induced seismicity associated

with Oil and Gas Development. North Dakota did not provide data for the primer, but state regulators participated as technical advisors to the IOGCC working group.

Access to this study benefits North Dakota citizens and regulators alike. We encourage North Dakotans to review the IOGCC document and become informed on our states very

low risk for seismic activity. Specific examples of how low risk North Dakota geology is, as well as how North Dakota compares to states with known stresses or faults

can be found on pages 9 and 107 of the IOGCC study. For state regulators, this document provides valuable insight from other states with known induced seismicity. If a

very unlikely event should occur in our state, North Dakota regulators can draw on the experience of others to make informed decisions.

In early 2016 the United States Geological Survey released a one year induced seismicity risk

assessment, which detailed six states that are at risk for earthquakes due

to deep water injection. North Dakota is one of the forty-four states determined to not be at risk for induced seismicity.

What are treating plants?

Treating plants are closely related to the Oil and Gas Division's UIC program and have similar

requirements, because both treating plants and SWD's handle oilfield waste and sometimes share the same location. Treating plants separate oilfield wastes such as drill

cuttings and tank bottoms from the oil and saltwater. Recovered oil is then sold, while the cuttings and other separated waste are dried for burial in special waste

landfills. Saltwater is disposed of in the onsite SWD or at another authorized SWD. If the location is not shared, saltwater is trucked or piped to the offsite SWD.

Treating plants are similar to a recycling facility in that they recover additional resources and prolong the life of special waste landfills.

How are EOR and SWD wells plugged?

When any well is plugged in North Dakota, it must first receive approval of the

plugging procedure and the plugging operations are then witnessed by an Oil and Gas Division field inspector. Typically, cement is pumped down hole to isolate, or

"seal-off" the injection zone from the well bore and other formations. A tool, called a cement retainer, is placed down hole to "squeeze" or pump cement into any

perforations that had been placed into the casing. Otherwise, cement is placed like a "plug" in the wellbore. Additional cement plugs are set in the well bore to

permanently isolate oil, gas, and water formations from fresh water formations and to seal the well bore at the surface. The well casing is cut off deep enough to

prevent interference with agriculture or utility construction and a metal plate is welded onto the cut-off casing.

|